Innovative solutions to improve workplace safety and reduce risk

With safety at the forefront of everything we do, eliminating live work is a priority at Komatsu. This involves eliminating work that occurs within the operating footprint of an energised machine. Working in the environment of an energised machine, workers are exposed to some of the highest risks in the industry.

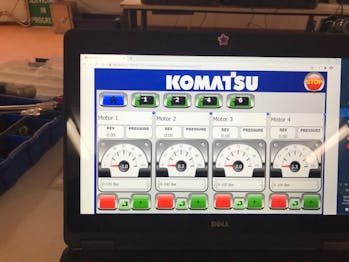

Komatsu is focused on live work elimination through the development of innovative and agnostic tools such as Tunesafe.

Tunesafe adjusts the machine, while removing people from the line of fire, by putting a robotic hand in place. Tunesafe allows remote adjustment of the pressure relief valves on live machines from inside the cab.

In addition to Tunesafe, Komatsu has introduced a Bluetooth dial gauge to complete brake disk wear measurements and centre hinge pin bearing clearance measurements that are applicable on all models. This allows a technician to take measurements safely from inside the cab, removing them from the line of fire.

Komatsu has also introduced a Bluetooth oil pressure sensor that is applicable for all models. This tool allows remote data collection of oil pressure during inspection, troubleshooting, and testing & adjustment. These measurements can be taken safely even when the machine is operated by a single operator. The use of remote data collection couples perfectly with Tunesafe.